ERP Software Development for Chemical Manufacturers

- Advanced enterprise resource planning system for the chemical manufacturing industry

- Automated procurement and equipment management, time tracking and reporting to optimize production schedules and minimize inventory investments

Iflexion delivered a simple and lightweight, yet powerful ERP system available as a SaaS application and tailored to the specific needs of the chemical manufacturing industry.

Context

Our Customer is a global provider of practical asset management and regulatory compliance solutions for chemical manufacturing enterprises throughout North America. The Customer decided to develop an easy-to-use ERP solution to help a chemical manufacturing company manage a variety of complex production processes, employee activities, and equipment.

To implement the idea, the Customer needed a reliable ERP software development provider with strong business analytical skills, who would get deep into the chemical manufacturing business domain and deliver an adequate solution. Iflexion got engaged in the full-cycle project development as the Customer’s trusted long-term technology partner.

Solution

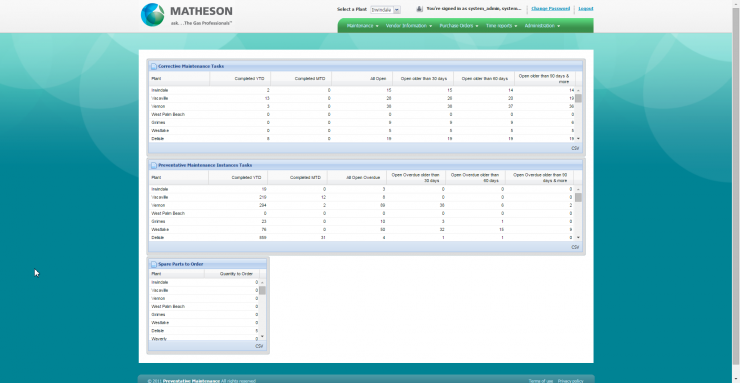

Leveraging a solid expertise in ERP systems implementation along with the complex enterprise software development, Iflexion delivered a fully functional solution enabling the End Customer to manage their equipment, spare parts, and consumables, as well as control the production lifecycle and employee performance in geographically distributed networks of manufacturing plants.

The solution provides role-based access to all employees, from top managers to technical specialists:

- User. An employee, who manages equipment maintenance tasks, submits purchase orders, and logs working time.

- Manager. In addition to the User functions, managers deal with vendor lists, track employees’ working time and manage vendor invoices.

- Corporate user. A top manager who can access corporate dashboards and reports generated by all departments throughout the corporation.

- Administrator. A user who performs content and user account management, as well as configures the system within their plant(s).

- System administrator. Having full access to the system, an administrator is responsible for the overall system configuration on the corporate level.

Tailored to the needs of the chemical industry, the custom ERP system supports typical workflows of chemical manufacturing, including equipment maintenance, accounting of consumables and spare parts, procurement management, and employees’ work time tracking.

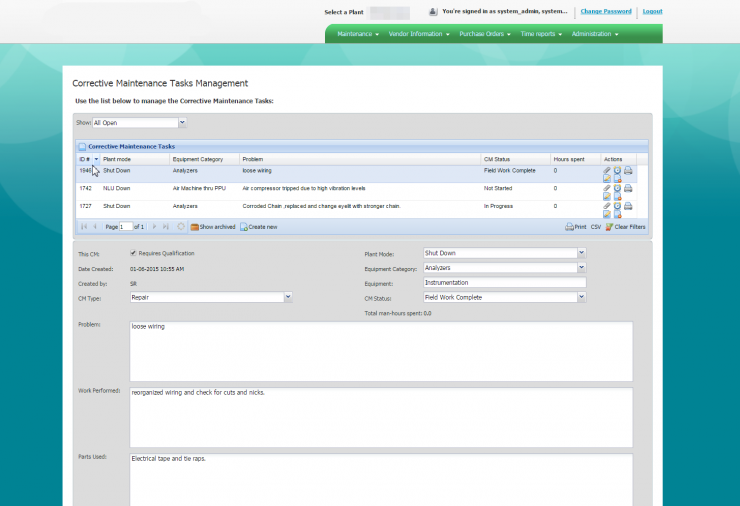

Equipment Maintenance

The ERP system allows for keeping track of all tasks related to the equipment maintenance. Built in line with the company’s established business processes, the solution covers the following maintenance types:

- Preventive Maintenance includes equipment tests, adjustments, parts replacement and cleaning, and other actions performed to prevent failures.

- Corrective Maintenance covers the repair of failed equipment in order to restore its operability.

Apart from that, end users can create, edit and remove emerging tasks on equipment repairing, log time spent on these tasks in individual timesheets, mark task statuses (in progress, delayed, fixed, overdue etc.), leave comments, upload files and more.

Procurement Management

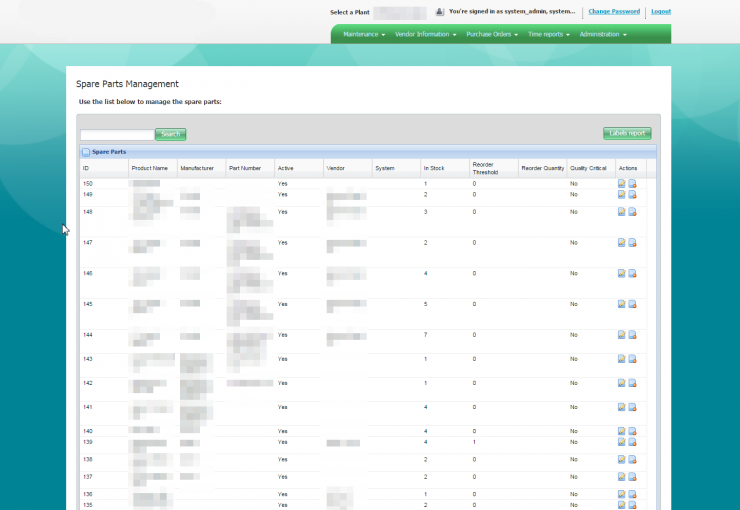

Applying our experience of supply-chain solutions implementation, Iflexion automated the accounting of spare parts and consumables.

The system stores an extended list of spare parts and consumables, each one attributed a full name, catalog number, manufacturer, vendor and current amount on stock. A user can also define a threshold amount, upon reaching which the system generates a purchase order automatically.

The system also keeps a full vendor list with all contact information used for purchase orders and invoices generation.

To ensure transparency of all banking operations related to procurement, our team implemented report generation feature. Top and senior managers can also access batch header reports describing banking transactions within each purchase order.

Employees’ Work Tracking

To support manufacturing workflows, Iflexion implemented an issue tracking engine that enables users to organize tasks, assign tasks to defined employees, as well as follow employee, department and plant activities. Based on the manually logged information (time spent on a task, issue status etc.), the system generates extended time reports for the top and middle management:

- Individual timesheet reports

- Group timesheet reports for a period of time (for departments and plants)

- Biweekly reports summarizing employees’ general performance across a plant

Development Process

Iflexion was the sole vendor of ERP software development at all project stages, including:

- Requirements analysis

- Architecture design

- ERP Development

- Quality Assurance

- Support and Maintenance

Collaboration with the End Customer started with a thorough examination of business requirements. As the project was built around a SaaS-based ERP system for a narrow industry segment, our business analysts researched the chemical manufacturing domain and determined crucial features that could bring additional value to the chemical plants.

The End Customer’s primary goal was to get a lightweight and highly performing ERP system at an affordable price. Our team concentrated on the most valuable features in order to cut down the software implementation costs.

As soon as the End Customer approved the offered business logic of the future solution, Iflexion got down to the system implementation. At the project management level, Iflexion provided the Customer with weekly reports on the completed tasks to let them follow the project dynamics.

Quality Assurance

To ensure the system’s high quality and to align it with the project requirements, our quality assurance specialists monitored and tested the software at the pre-development, development and post-development stages.

Iflexion allocated an independent quality assurance department to perform comprehensive quality assurance of the system. Within each iteration, the team fulfilled unit, acceptance, regression and compatibility testing, and defect validation.

Results

The delivered ERP-system brings in transparency and order into the End Customer’s business processes, which makes it particularly valuable for strictly disciplined chemical plants. Deployed at 50+ plants, the solution allowed the company to improve equipment, inventory, and procurement management processes significantly. Satisfied with the cooperation, the Customer prolonged collaboration with Iflexion, delegating the system enhancement to our professional team.

Screenshots

-

![]()

Custom ERP to optimize operations at Toyota Motor Corporation

FULL CASE STUDYIflexion provided ERP development services for one of the largest Toyota dealerships to foster their business processes through an effective software solution.

-

![]()

Custom CMS Development and Intranet for Philips Consumer Lifestyle

FULL CASE STUDYIflexion delivered a custom OpenCms-based content management system and enterprise portal on top of it to provide Philips Pronto, a subdivision of the global producer of electronics and domestic appliances, with the benefits of open source technologies.

WANT TO START A PROJECT?

It’s simple!